1、 What is non-standard equipment

Non standard equipment refers to equipment which is not produced according to unified national standards and general specifications, but is customized and designed and manufactured according to actual needs. It has the characteristics of specialized machine, small batch, multifunctional, multi type, and high complexity.

Wherever there is a demand for machine replacement, there will be non-standard automation equipment. It involves a wide range of industries, covering almost all industrial and production fields, with a market space of billions. Its main participants are professional non-standard automation equipment manufacturers and automation departments under large manufacturing enterprises.

2、 Industry pain points of non-standard equipment

In the fierce market competition, customers' requirements for non-standard automated production lines are mainly: ① short construction period, low investment, and low risk; ② Short order switching time; ③ Capable of quickly and cost effectively iterating and upgrading production lines, compatible with the manufacturing of new products; ④ There are relatively few types of standard and customized parts, and the difficulty of spare parts management is low, without demanding high skill levels from users and maintenance personnel. In order to solve the contradiction between the non-standard customized design conditions of automated production lines and the actual needs of customers, achieve the goal of shortening project cycles, reducing design costs, improving design quality, and meeting customer needs, it is necessary to find an effective method for rapid design and high-quality management of non-standard automated production lines.

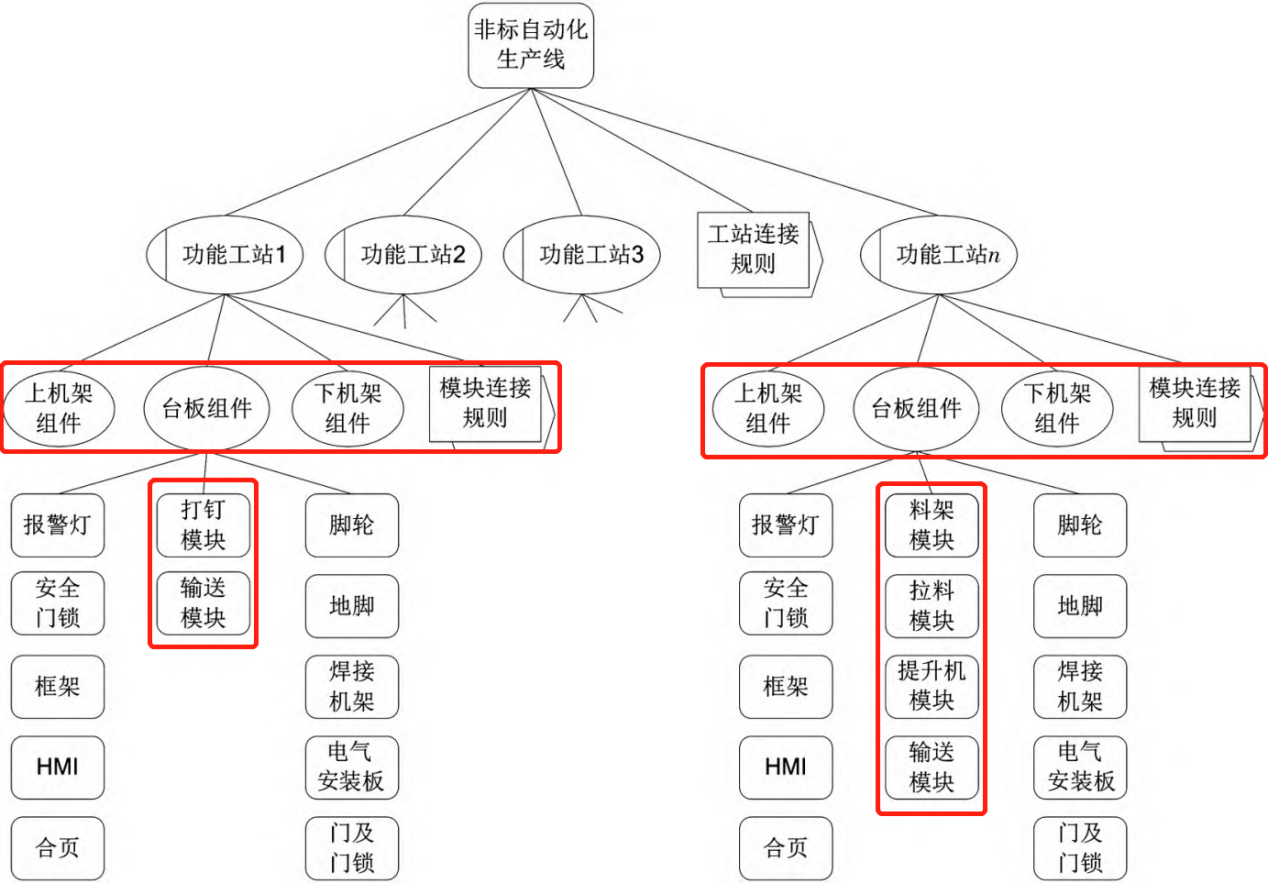

A typical structure of non-standard automated production line

3、 What problems can modularization solve

The concept of modularization was officially proposed by some European and American countries in the 1950s, and subsequently received increasing attention and research. In the field of automation equipment, modularization refers to dividing the equipment into multiple modules with specific functions, which can operate independently or be linked with other modules. Each module has independent functions and interfaces, making it easy to combine and replace, and improving the flexibility and scalability of the equipment. At present, modular design methods have been applied in multiple industries such as machinery, electronics, ships, and construction. Some equipment manufacturers have applied modular thinking to equipment production, improving the overall manufacturing speed of equipment by pre assembling commonly used modules. Modularization has the following advantages:

(1) Shortened the design and manufacturing cycle. When users make a request, they only need to replace a certain module or directly call an existing module to meet the new design requirements, which greatly shortens the design and manufacturing cycle.

New product=universal module (unchanged part)+modified module (variable part)+new functional module (dedicated part)

(2) Improve equipment flexibility. By quickly replacing functional modules, device flexibility can be improved to meet the needs of small batch and fast delivery equipment usage.

(3) Reduce manufacturing difficulty. After modularization, the quantity and specifications of equipment BOM are reduced, greatly reducing the difficulty of supply chain and production manufacturing management.

(4) Reduce costs. After modularization, the same functional module can be used for multiple products, and cost reduction can be achieved through large-scale production.

(5) Easy maintenance. When repairing the product, only the damaged module needs to be replaced, making the repair convenient and fast.

(6) Stable and reliable performance. Modular design makes the product structure relatively fixed, allowing manufacturers to conduct careful research and gradually improve product stability.

4、 The Practice of Modularization

At present, some manufacturers have also begun to experiment with modular supply, which requires component manufacturers to have a multi category layout industry foundation and the ability to integrate supply chains.

Yiheda has launched its own modular products on its official website, which are divided into grasping components, conveying components, feeding components, other functional components, and electronic control integrated cabinets according to their functions.

Jialichuang has also launched its own modular products, including top lifting rotary machines, top lifting transverse machines, elevators, forced turntables, conveyors, etc.

Tianyi Intelligent was established in 2013, mainly engaged in the research and development, production, sales, and service of precision standard parts and functional modules, as well as the production and manufacturing of tooling fixtures and automation equipment (lines). The company has been serving top customers in the industry for a long time. Based on years of accumulation, it has completed a multi category and customer-oriented industrial layout. With close cooperation with the industrial chain, it can provide customers with modular products and services, helping them improve efficiency and reduce costs.